-

Products

-

Trunk transport or long-haul transport

Using steel-aluminum structure and three-dimensional finite element simulation optimization, the body weight is lighter and the structure is more scientific.

-

Side curtain semi-trailer

The side curtain vehicle, that is, the side curtain transport vehicle, that is, the transport vehicle with one side or both sides of the cargo compartment as curtain fabric structure.

-

Fresh milk transport semi-trailer

Milk transport semi-trailer is also called milk transport vehicle, milk tanker and liquid food transport vehicle.

-

Van transport semi-trailer

Provide customized services, according to different standards in your country, we match the best solution for you.

-

Special container for logistics

Easy to deal with all kinds of loading and unloading situations, safe and secure.

-

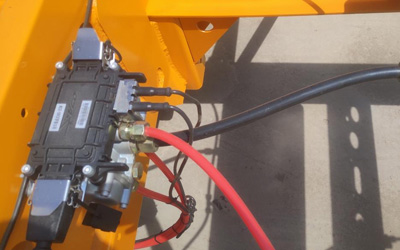

Customization device

Provide customized services, according to different standards in your country, we match the best solution for you.

Products

-

Trunk transport or long-haul transport

- News

- Service

-

About

-

Company

Headquartered in Yubei Industrial Park, China, the company has been a logistics and transportation equipment solution provider integrating production, scientific research and sales since its establishment in 2005.The com...

-

Honor

Each vehicle has undergone rigorous tests to meet the standard requirements, and the trunk has undergone air tightness tests and records, and it is confirmed that each vehicle has files and records....

About us

-

Company

- Videos

- Contact